CGM can provide the best Quality Disperse Calcium Carbonate:

CGM can provide the best Quality Disperse Calcium Carbonate:

The dispersion of calcium carbonate is generally achieved by milling of a calcium carbonate mineral (for example, limestone, chalk, whiting, or more preferably marble) in water with a dispersing agent; the dispersing agent used in the milling is usually a selective copolymer of AMPS and acrylic acid.

Disperse CaCO3 is a suspension of CaCO3 in water (aided by a dispersing agent). Wet grinding enables us to create our very efficient and effective paint extender. The simple aim of creating dispersed CaCO3 is to reduce the total cost of paint and provide better sheen, smoothness, flowability and coverage. When wet grinding the CaCO3 particles are suspended so evenly that they provide higher coverage than when ground on dry-ground CaCO3. In addition, our CaCO3 in slurry form will reduce the electric cost and chemical cost as it is pre-disperssed which means less need for dispersant and biocides. We also have a variety of products available to meet our customers’ needs.

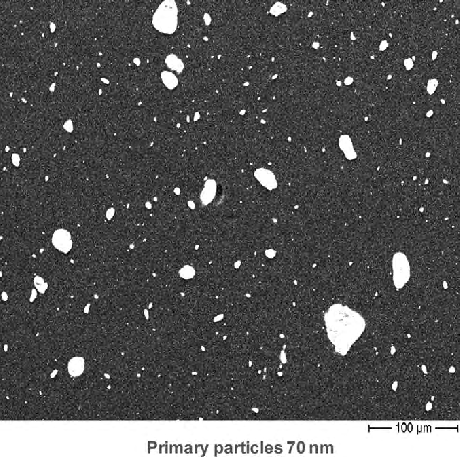

Calcium Carbonate Nanoparticle Dispersions are suspensions of calcium carbonate nanoparticles in water or in various organic solvents such as ethanol or mineral oil. Nanochemazone produces compound nanopowders and nanoparticles with typical particle sizes ranging from 10 to 200 nm, available in both coated and surface-functionalized forms.

Chaudhry Grinding Mills Copyright 2025 All Rights Reserved | Proudly Designed by WebTeknes.